|

KLINKAU FILTER PLATE APPLICATIONS 應用實例 |

CHEMICAL INDUSTRY 化工業

|

The filtration of chemicals at temperatures between –10 to 95 degree centigrade requires a careful selection of membrane resins. The ideal solution for many chemical filtration applications is the welded KLINKAU membrane plate in the standard and "Empty Chamber" design with corner feed and no stay-bosses in the filtration area for optimum performance. 1200mm x 1200mm membrane filter press utilizes a special corner feed design for an aggressive acidic slurry filtering at 80 degree centigrade. |

|

KLINKAU 1500mm x 1500mm center feed "ALL" Membrane Filter Plate stack in standard welded design has been operated since 1987 in the production of Azo pigments. |

FOOD INDUSTRY 食品業

|

Beer Mash Filtration requires a bottom external feed eye inlet

to enable a smooth filtration with very little oxygenation in

the wort.

|

|

|

Sugar industry standards

require a minimum of 70% solids in the cake and a maximum of

0.5% sucrose content remaining in the filter cake. This high

extraction rate must be achieved with a minimum of high

temperature wash water not exceeding the cake volume. Cycle

times between 12 and 30 minutes in a 24 hour operation at

temperatures between 80 and 85 degree centigrade require a

durable filter plate to meet these extreme parameters.

Thousands of KLINKAU membrane filter plates worldwide are in

operation under these requirements. This specially designed external top feed eye membrane filter plate provides excellent filtration and wash results. |

|

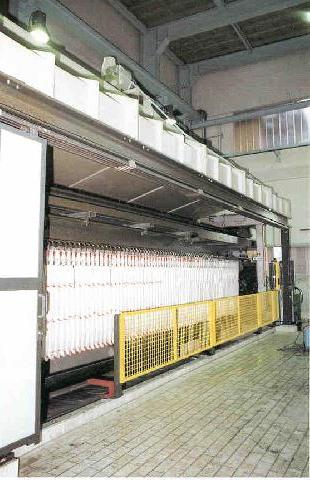

This 1500 mm x 1500 mm membrane filter press utilizes a Klinkau "Empty Chamber" mixed pack corner feed membrane filter plate system to filter rice mash in the production of Sake Moromi rice wine. |

|

This 1500mm x 1500mm filter press is supplied with a KLINKAU Replaceable mixed pack membrane filter plate system to achieve short cycle times and high cake solids in this wastewater sludge application. The high efficiency of the KLINKAU mixed pack membrane plate system provides an increased economical return by minimizing the disposal costs |

|

濾水處理廠 明礬化学淤泥脫水處理 This 1500mm x 1500mm filter press is supplied with the KLINKAU Replaceable Overhanging "Empty Chamber" mixed pack membrane filter plate system to achieve cake solids over 35% in this water filtration polymer conditioned alum sludge application. The overhanging replaceable membrane can be easily replaced within the framework of the filter press

|

|

The recessed chamber filter plate filter press is an economical solution for the solid / liquid filtration phase of the treatment process. This 1500mm x 1500mm filter press utilizes top-center feed recessed chamber filter plates to dewater the slurry from the soil remediation treatment process. Landfill management to process the leachate from the landfill, and industry to remediate contaminated soil and groundwater. |

PHARMACEUTICAL INDUSTRY 藥劑工業

|

KLINKAU filter plates are utilized in many pharmaceutical filtration applications requiring sterile operation and FDA – approved virgin and co-polymer polypropylene resins. This all stainless steel filter press utilizes a 1200mm x 1200mm "Empty Chamber" mixed pack corner feed membrane plate system. Due to extreme operating criteria for cake washing, the filter plates are designed with corner feed and no stay-bosses in the filtration area. The filter plates met all requirements for cake dryness and cake washing. |

CERAMIC GLAZE / SLIP AND CLAY INDUSTRY 瓷工業

|

Ceramic and Clay applications require high volume production and low cake moisture content. The KLINKAU product line of membrane and recessed chamber filter plates rated for 300psig –20 bar operation can be utilized to meet the demands of these applications. This 1500mm x 1500mm membrane filter press was converted from rubber membranes to the KLINKAU "Empty Chamber" membrane plate design. The "Empty Chamber" design membrane plate system reduced the cake moisture from approx. 32% to 28% while reducing the cycle time from 75 minutes to 60 minutes. |

PALM OIL FRACTIONATION 棕櫚油 分離

|

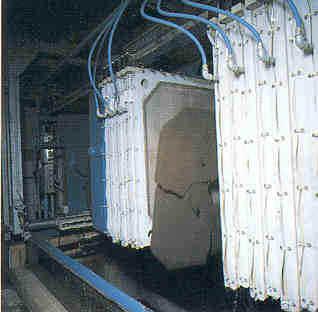

The complete KLINKAU membrane product line ( fixed welded –standard , fixed welded- "empty chamber", replaceable membrane- "empty chamber") has been successfully utilized for over 15 years in the fractionation process of palm oil filtration. Refined bleached palm oil is being cooled to approximately 20 degrees centigrade by the crystallization process to crystallize the saturated fatty acids. The crystallization suspension is then filtered utilizing the membrane filter press. The filtration process will yield the valuable oleon ( filtrate ) and stearin ( filter cake ). An evenly formed filter cake during the filtration phase and a uniform movement of the membrane during squeezing has a great influence on the separation of the oleon. The operation and results of the membrane filter plate system are a major economical factor in the fractionation process. The method of construction on the KLINKAU membrane product line guarantees an even cake formation and therefore a defined squeeze result that produces high yield and quality product. The latest development is the special KLINKAU anti-static membrane to eliminate electrostatic energy within the filter press. This 70 chamber, 1450mm x 1450mm palm oil filter press utilizing the KLINKAU fixed welded – standard membrane filter plate system has been in operation since 1988. The plate system includes the corner feed design with 40mm cake thickness. |

METALS REFINING INDUSTRY 冶金工業

|

A recessed chamber

filter press can be chosen for metals recovery applications

utilizing a wash system to increase the product yield. Typical

applications include intermediate and final refining steps of

cadmium, zinc, decopperizing, repulping, recovery, and primary

metals leaching. This 1500mm x 1500mm filter press utilizes recessed chamber filter plates in the recovery process of cadmium from bag house dust. |

|

A Filter Press may be utilized in many different types of filtration processes in the Blood Processing Industry. Plate / frame and membrane filter plates are mainly utilized in these blood processing applications. There are also KLINKAU membrane filter plates in very special design and resin modifications operating in Blood Plasma Processing applications This 1200mm x 1200mm Klinkau "Empty Chamber" mixed pack corner feed membrane filter plate system with 316L stainless steel feed eye grommets was designed for filtering bovine blood serum at temperatures -5 degree to 25 degree centigrade. The filter plates are molded from a special resin to operate in the cold temperature application. The maximum feed pressure is 100 psig – 8 bar and the maximum squeeze pressure is 225 psig – 16 bar. |

Material Comparison between Mild Steel rubber Coated Plate and PP Plates

Home Contact Us Products Photo Gallery